When it comes to construction projects, the quality of building material used during construction greatly determines the finished product. High quality materials will result in world class projects that are built to withstand the test of time.

The responsibility of checking on quality of building material procured by the contractor lies with the consultants. The structural engineer prepares the project specifications for all building material and applicable standards they should comply with. The architect will check on quality of finishes mostly and the quantity surveyor, as the cost expert will advise on cost of what has been procured vis a vis what had been provided for in the bills of quantities.

It is possible to determine whether a product is substandard or not just by physical inspection, without having to go to the lab and carry out tests. We have listed the most common construction materials in use and what you should look out for when purchasing to ensure you get the right product.

(Disclaimer: Please note that the information contained in this article is intended for educational purposes only, and should not be substituted for professional advice. Always engage a building professional in your project to ensure you get good quality building products.)

Building Stones

Building stones can either be manually cut or machine cut.

- Foundation stones are normally manually cut and have rough, uneven surfaces. They are sold per running foot. These should be very strong and heavy to lift and most importantly not porous i.e the rate of water absorption/seepage from outside is very low.

- Machine cut stones are preferred for walling since they are well shaped with even surfaces. This helps in saving on time and labor cost that would have gone into dressing. They are sold per piece. Ensure the stone is compact i.e does not easily deteriorate and is free from cavities or cracks especially on the edges/corners. You can also check the rate at which the stones are breaking as they are being unloaded from the delivery truck. If many stones break then chances are that they are not good quality.

Sand

Good quality sand should be well graded (meaning contains particles of a wide range of sizes). However, it is important to note that sand to be used for concreting works is generally coarser while for plastering works tends to be finer. When placing your order for sand, make sure you mention what you want to do with it to your supplier so that they deliver the most suitable sand for your needs.

It is important that the sand is clean and free from clay. If you rub a sample of the sand with wet palms, it should not stick together. If it does, then it means there is prescence of clay since sand is cohesionless and clay is cohesive. You can also physically examine to check for hints of dirt/impurities in the sand.

Ballast

For concrete works, the ballast should be clean and have a mixture of both big and small sized particles (well graded) for best results. The smaller the size of ballast, the greater its surface area and the more binding material (cement) will be required, resulting in a higher cost. The greater the size the larger will be the voids, resulting in wastage of binding material (cement).

Timber as a building material

Different forms of timber are used extensively in various phases of construction. It can be used as formwork, props for scaffolding, roofing trusses or for finishes.

The general rule is to ensure timber is free from defects such as dry rot, wet rot or blue stain but most importantly should be well seasoned i.e well dried with very low moisture content. Using unseasoned timber could result in the timber members warping after some time. It is difficult to determine the moisture content of timber just by examining physically. Which is why I always recommend that you buy timber from a reputable company that can show you the moisture content of your wood using a moisture content meter.

Roofing Material

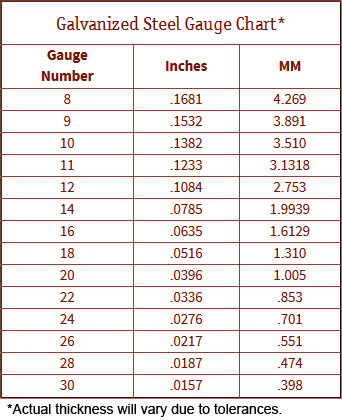

When buying metal roofing which could be in the form of corrugated iron sheets, box profile sheets etc, you need to emphasize on the gauge, meaning the thickness of metal; the higher the gauge, the thinner the roofing sheet.

It is best to purchase roofing material directly from the manufacturer. That way, you know that the material is genuine and you can avoid knock offs that are being sold in local hardware store. Always request the manufacturer to provide a warranty in writing.

What are some of the challenges you’ve faced while sourcing for building materials? Let us know in the comment section!